Our Products :

Water purification is the removal of contaminants from untreated water to produce drinking water that is pure enough for the most critical of its intended uses, usually for human consumption. Only 1% water on Earth is used for domestic and industrial purposes so our utmost aim is to save this resource and protect it from contamination

Softening plants

Softening plant is used to soften the water, by removing the minerals that cause the water to be hard. Minerals like calcium and magnesium present in the water in their carbonates and bi-carbonates form makes the water hard which creates many problems when it is used in industrial as well as in other domestic purposes. We are accredited as one of the largest water softener plantsuppliers.

Demineralised Plant

In the process of Demineralized Water Plant System the bi-functional group attached to Cation and Anion resin plays a vital role in exchanging process of ions. Removal of all dissolved minerals present in water virtue of Cation and Anion resin technology is called "Demineralization Process". Different types of schemes available in D.M. Plants depend on raw water composition and the end quality requirement of water. Demineralization plant performs efficiently in purifying and removing varieties of impurities from water.

Reverse Osmosis system

Reverse osmosis is often used in commercial and residential water filtration. It is also one of the methods used to desalinate seawater. The Domestic reverse osmosis system is the reverse osmosis system that purifies the water that you drink, giving it great taste and removing everything that could harm you in the short and long term.The semi permeable membrane allows the passage of water, but not ions (e.g., Na+, Ca2+, Cl-) or larger molecules (e.g., glucose, urea, bacteria).

Effluent treatment plant

It is an informative good practice that deals with improving the performance of effluent treatment plant to reduce operating costs and reduce environmental pollution. Effective management and control of the processes used for effluent treatment will help us to:

- Reduce our operating costs and thus increase profits.

- Achieve more effective compliance with legislation.

- Improve our company's public image.

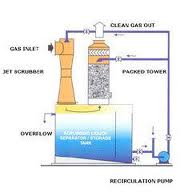

Wet scrubbers

The Packed Bed Scrubber, or Packed Tower, is designed to remove gaseous or vaporous pollutants from an air stream. The process is accomplished by contacting the contaminated air stream with a scrubbing liquor that absorbs or chemically reacts with the pollutants. Some vapors can be simply removed by condensation through the cooling effect of the circulating liquid. The cleaned air is then discharged to the atmosphere and the contaminated scrubbing liquor is either disposed of in an approved manner or chemically treated and recycled.

Packed bed

A Venturi scrubber is designed to effectively use the energy from the inlet gas stream to atomize the liquid being used to scrub the gas stream. This type of technology is a part of the group of air pollution controls collectively referred to as wet scrubbers.

Venturi scrubbers

A Venturi scrubber is designed to effectively use the energy from the inlet gas stream to atomize the liquid being used to scrub the gas stream. This type of technology is a part of the group of air pollution controls collectively referred to as wet scrubbers.

Bag filters

Bag Filters are typically constructed from porous woven or felted fabric, tube-shaped, which gases are flowed through to remove particulates / contaminants. Contaminants larger than the porous openings within the bag filter allow the gas to pass through however trap the larger contaminant particles.

Waste water treatment plant

Treatment of sewage is essential to ensure that the receiving water into which the effluent is ultimately discharged is not significantly polluted. However, the degree of treatment required will vary according to the type of receiving water. Thus, a very high degree of treatment will be required if the effluent discharges to a fishery or upstream of an abstraction point for water supply. Our aim is to treat the waste water and use it for gardening.

Sewage treatment plant

Sewage Treatment Plant is a facility designed to receive the waste from domestic, commercial and industrial sources and to remove materials that damage water quality and compromise public health and safety when discharged into water receiving systems. The Principal objective of waste water treatment is generally to allow human and industrial effluents to be disposed of without danger to human health or unacceptable damage to the natural environment.

Air pollution control :

The rise of environmental awareness has reminded people that air pollution ought not to be seen as a necessary product of industrialization. This has redirected responsibility for air pollution towards those who create it. The notion of "making the polluter pay" is seen as a central feature of air pollution control. Air quality management strategies that set ambient air quality standards so that emissions from various sources can be monitored and controlled;

Dust collector

A Dust Collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas.

Acid fume extraction

The Acid Fume Collectors is mainly designed to avoid the health hazards and temperature rise in the critical areas of acid fume generation.Dissolved air flotation (DAF) is a water treatment process that clarifies wastewaters (or other waters) by the removal of suspended matter suEmission standards strategy that sets limits for the amount of pollutant that can be emitted from a given source;

Economic strategies that involve charging the party responsible for the pollution. If the level of charge is set correctly, some polluters will find it more economical to install air pollution control equipment than continue to pollute.

Cost-benefit analysis, which attempts to balance economic benefits with environmental costs. ch as oil or solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank or basin.